Building a DIY Bluetooth speaker requires 10 core steps: gathering essential components (Bluetooth module, Class D amplifier, 4-8Ω speakers), selecting an appropriate enclosure material (MDF or acrylic), calculating internal volume (0.1-0.5 cubic feet), installing the power system (12.8V lithium-ion battery), wiring components securely, adding acoustic dampening, mounting drivers properly, connecting the amplifier board, testing sound output, and fine-tuning equalization. Following these technical guidelines guarantees ideal audio performance and system reliability, with deeper exploration revealing additional optimization techniques.

Key Takeaways

- Gather essential components including a Bluetooth module, Class D amplifier board, quality speaker drivers, and a lithium-ion battery pack.

- Design and build an MDF enclosure with proper dimensions and acoustic foam lining for optimal sound quality.

- Wire the speaker drivers correctly, ensuring proper impedance matching with the amplifier (4-8Ω range).

- Connect the Bluetooth module to the amplifier board and install the battery pack with protection circuits.

- Test the system’s sound quality, adjust equalizer settings, and verify battery charging functionality.

Gathering Essential Components and Tools

The initial phase of building a Bluetooth speaker requires assembling a complete set of essential components and appropriate tools. Before making any purchases, a thorough budget estimation helps guarantee all necessary items can be acquired cost-effectively through supplier comparison. Core electronic components include a reliable Bluetooth module, Class D amplifier board, quality speaker drivers, and a lithium-ion battery pack for power. Essential tools comprise a soldering iron, wire strippers, and basic drilling equipment for enclosure preparation. The assembly process also requires acoustic materials like dampening foam, protective grills, and appropriate enclosure materials, which may include wood or high-grade plastic. Additional items include control interfaces such as LED indicators, power switches, and necessary connectors. Carefully selecting high-quality components ensures better sound performance and longer-lasting durability connectivity options, which are key factors in building an effective Bluetooth speaker.

Planning Your Speaker Design

The foundation of any successful Bluetooth speaker build begins with calculating power requirements based on desired volume levels, battery life expectations, and amplifier specifications. Proper driver selection involves matching impedance ratings, frequency response ranges, and power handling capabilities to achieve ideal audio performance within the planned design parameters. The enclosure dimensions must be precisely calculated to accommodate the chosen components while maintaining proper acoustic volume, typically ranging from 0.1 to 0.5 cubic feet for portable speakers, which directly impacts bass response and overall sound quality. Additionally, selecting the right speaker power output is essential for ensuring even sound distribution in larger spaces over 200 square feet.

Determine Power Requirements First

Planning power requirements stands as the essential first step in designing any Bluetooth speaker system, requiring careful consideration of multiple electrical specifications and performance targets. Builders must evaluate both power sources and energy consumption patterns to guarantee ideal performance and longevity.

The process begins with determining the speaker’s continuous power (RMS) rating and peak power handling capabilities, typically ranging from 3-30 watts for portable designs. Understanding sensitivity ratings helps calculate the amplifier power needed, while factoring in desired sound pressure levels and headroom for audio peaks guarantees clean, undistorted output. Standard voltage requirements of 5V/2.3A through USB power or external adapters must be matched with appropriate battery capacity for portable use. Additionally, proper heat dissipation and thermal management systems protect components while maintaining efficiency during extended operation.

Select Suitable Driver Components

Selecting suitable driver components marks a critical phase in Bluetooth speaker design, requiring careful evaluation of specifications and performance characteristics to achieve ideal audio quality. When choosing drivers, builders must consider their impedance ratings, power handling capabilities, and frequency response ranges to achieve ideal performance with the chosen amplifier.

The selection process involves evaluating the dispersion profile for even sound distribution and examining coil materials, typically copper or aluminum, for efficient power handling. Full-range drivers prove ideal for compact designs, while larger projects may benefit from separate woofers and tweeters. Key considerations include driver size, which affects bass response, and sensitivity ratings that determine volume capability. For portable speakers, efficiency becomes paramount to maximize battery life, while durability features protect against environmental factors like moisture and dust.

Choose Enclosure Size Carefully

Proper enclosure sizing stands at the foundation of successful Bluetooth speaker construction, building upon the careful driver selection process to maximize acoustic performance. For ideal bass frequency response, designers should match internal volume to driver diameter, with 2.5-6.5″ woofers typically requiring 0.06-0.33 cubic feet in sealed enclosures.

The enclosure’s geometry plays a vital role in managing wave patterns and preventing acoustic distortion. Rectangular shapes with asymmetric internal dimensions help reduce standing waves and resonant peaks, while 3/4″ thick materials provide ideal rigidity for most bookshelf-sized builds. Internal damping, achieved through strategic placement of acoustic foam or polyfill, can increase apparent volume by up to 15%. Online calculators and design tools enable precise volume calculations, ensuring ideal performance for specific driver configurations.

Selecting the Right Speaker Drivers

Selecting appropriate drivers requires careful consideration of their power handling ratings, impedance specifications, and physical dimensions to guarantee compatibility with the amplifier and enclosure design. While larger drivers generally produce better bass response, size must be balanced against the speaker’s intended portability and cabinet volume requirements, with 3-4 inch drivers offering a good compromise for most Bluetooth builds. The drivers’ impedance levels, typically 4 or 8 ohms, must match the amplifier’s specifications to prevent damage and achieve efficient power transfer through the system. Additionally, high-quality materials such as titanium or silk domes can enhance durability and sound clarity in your homemade speakers.

Understanding Driver Power Ratings

When building a Bluetooth speaker, understanding driver power ratings forms the critical foundation for achieving ideal audio performance. Builders must grasp the difference between RMS basics, which represent continuous power handling capabilities, and Peak bursts that indicate maximum short-term power capacity. The RMS rating typically measures sustained performance, while peak power handling can reach up to four times this value for brief moments.

Speaker enthusiasts should focus on selecting drivers with appropriate power specifications that match their amplifier’s output. A driver’s continuous power handling should align with the amplifier’s RMS output, ensuring safe and distortion-free operation. The program power rating, usually double the continuous rating, provides essential headroom for dynamic audio passages. This careful matching prevents thermal and mechanical damage while optimizing sound quality.

Size Vs Sound Quality

The relationship between driver size and sound quality represents one of the most crucial decisions in Bluetooth speaker construction. When selecting drivers, builders must balance the trade-offs between size and performance characteristics. Larger drivers (6 inches or more) excel at bass reproduction, delivering deeper low frequencies below 80Hz, while smaller drivers (1-2 inches) provide superior treble fidelity and detail in the high ranges.

For best results in portable speakers, a combination of driver sizes often yields the best performance. A typical configuration pairs a 3-5 inch mid-woofer with a 1-inch tweeter, creating balanced sound across the frequency spectrum. The enclosure size must match the chosen drivers, with larger drivers requiring more cabinet volume to achieve their full potential. Modern designs frequently utilize multiple small drivers to maintain sound quality while reducing overall speaker dimensions.

Matching Impedance Levels

Proper impedance matching between speakers and amplifiers forms the cornerstone of ideal audio performance in Bluetooth speaker construction. When selecting speaker drivers, builders must understand the fundamental Impedance Effects that influence sound quality and system reliability. Most amplifier modules work ideally with 4-8Ω speakers, making these impedance ranges ideal for DIY projects.

The Matching Principles involve careful consideration of the amplifier’s specifications and the speaker’s impedance rating. Builders should select speakers with impedance values that match or slightly exceed the amplifier’s recommended range. For example, pairing an 8Ω speaker with a 4-8Ω amplifier guarantees stable operation and prevents overheating. When using multiple drivers, remember that parallel wiring reduces total impedance, while series connections increase it. This knowledge enables constructors to create reliable, high-performance Bluetooth speakers that deliver ideal sound quality.

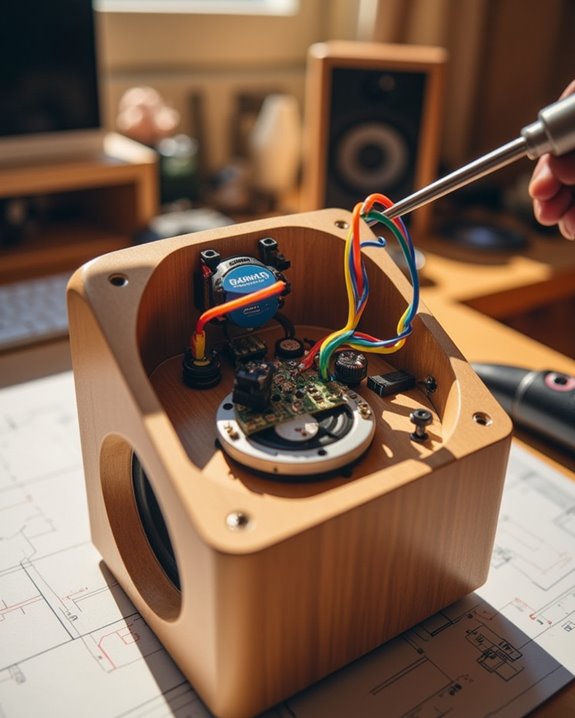

Building the Perfect Enclosure

Building an ideal Bluetooth speaker enclosure requires careful consideration of material selection, internal geometry, and acoustic principles to achieve superior sound quality. MDF serves as the ideal material choice, offering superior rigidity and vibration damping characteristics essential for clean audio reproduction.

Proper enclosure bracing becomes critical to minimize panel resonance at higher volumes, while strategic port tuning allows for enhanced bass response in compact designs. The internal volume must account for driver displacement, with calculations derived from manufacturer specifications or direct parameter measurements. Advanced builders can implement transmission line designs or passive radiators for improved low-frequency extension.

For superior performance, the enclosure should incorporate acoustic foam lining, precise driver mounting with pre-drilled holes, and chamfered edges around speaker cutouts to reduce turbulence. Double-wall construction provides additional benefits for high-power systems requiring maximum resonance control.

Installing Power and Battery Systems

With a well-constructed enclosure in place, selecting and installing an appropriate power system becomes the next critical engineering challenge. The choice between rechargeable lithium-ion batteries or deep cycle batteries determines the speaker’s overall Battery Lifespan, with most builders opting for 12.8V lithium configurations that offer maximum runtime.

Installing Protection Circuits remains essential for safeguarding the power system against overcharging and over-discharging. The setup typically requires connecting batteries either in series to achieve higher voltages (up to 25.6V) or in parallel to increase capacity. Proper implementation includes a DC charging jack, balanced cell monitoring, and efficient power management systems. The final configuration should match the amplifier’s voltage requirements while providing adequate power for sustained audio output, ensuring reliable performance during extended use.

Setting Up the Bluetooth Amplifier Board

The Bluetooth amplifier board serves as the central processing hub for wireless audio transmission and signal amplification. During setup, users must verify proper voltage connections and polarity alignment to prevent damage to sensitive components. The board requires a stable power source, typically 12-24V DC, for best performance.

Signal strength optimization involves strategic placement of the amplifier board away from metal enclosures and potential interference sources. Most modern Bluetooth amplifier boards feature automatic pairing functionality, though manual pairing buttons provide backup connectivity options. Regular firmware updates enhance compatibility with newer devices and improve overall system stability.

For reliable operation, installers should verify the following:

- Correct input voltage rating

- Antenna placement for maximum reception

- Heat sink attachment for thermal management

- Ground connection integrity

- Speaker impedance matching

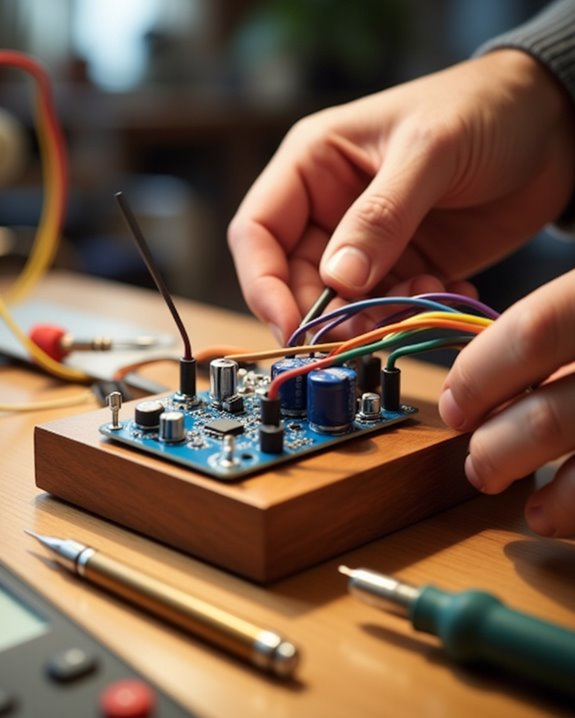

Wiring and Component Assembly

Precise wiring and systematic component assembly form the foundation of a reliable Bluetooth speaker build. The process begins with proper Wire Management, ensuring all connections between the 3.7V Li-ion battery, Bluetooth module, and speaker components are organized and secure. Experienced builders employ professional Soldering Techniques to create robust joints that withstand frequent use.

The assembly requires careful attention to polarity, connecting the battery’s positive terminal to B+ and negative to B- on the amplifier board. Proper grounding techniques and insulation are essential for safety and performance. Builders protect exposed connections using heat shrink tubing or electrical tape, preventing short circuits and moisture damage. The final step involves testing all connections before securing components in their designated positions, ensuring ideal audio output and reliable wireless functionality.

Sound Testing and Adjustments

Testing a custom Bluetooth speaker requires systematic validation of sound performance through basic volume and frequency checks. Using a decibel meter app positioned at 1 meter distance, measurements should be taken at 25%, 50%, 75%, and 100% volume levels to establish baseline performance and identify potential distortion points. The speaker’s frequency response can then be optimized through careful equalizer adjustments, focusing on key ranges like bass (20-200Hz), midrange (200Hz-2kHz), and treble (2kHz-20kHz) while monitoring for unwanted resonance or clipping.

Basic Sound Level Checks

Properly conducting sound level checks represents a critical phase in assembling and testing a Bluetooth speaker, guaranteeing ideal audio performance and quality control. The process begins with measuring ambient noise levels using calibrated sound level meters, which establish a baseline for testing against established safety standards.

Testing involves evaluating frequency response across the 20 Hz to 20,000 Hz range, with particular attention to the standard 1 kHz test tone for reference measurements. Audio analysis software generates precise frequency response graphs, while human listening tests provide subjective validation of sound quality. A systematic approach combines both technical measurements and practical evaluation, utilizing specialized equipment including calibrated microphones and frequency generators. This dual methodology guarantees thorough sound assessment, leading to ideal speaker performance through data-driven adjustments and refinements.

Equalizer Fine-Tuning Techniques

Mastering equalizer fine-tuning represents an essential phase in optimizing Bluetooth speaker performance, requiring both technical precision and systematic methodology. Through thorough audio profiling, builders can identify and adjust critical frequency bands across bass (20-250Hz), mids (250Hz-4kHz), and treble (4kHz-20kHz) ranges.

The signal processing approach involves using measurement microphones like UMIK-1 to analyze frequency responses and calibrate against standardized targets. Enthusiasts should leverage third-party equalizer applications while maintaining dynamic range within -3dB to prevent distortion. Critical adjustments include setting appropriate Q values for precise frequency control, applying strategic bass shelf filters below 90Hz, and validating changes through multi-genre testing. Documentation of pre- and post-EQ measurements guarantees systematic improvement tracking, while peer feedback helps confirm ideal tonal balance across different listening scenarios.

Adding Finishing Touches and Protection

Once the core components are assembled and tested, protecting the Bluetooth speaker with appropriate finishing touches becomes essential for long-term durability and performance. Basic weatherproofing measures, including clear silicone adhesive and strategic foam insulation, shield internal components from moisture damage and temperature fluctuations. The addition of reinforced corners, metal grilles, and dual-layer adhesive applications greatly enhance physical durability.

For aesthetic finishes and durability coatings, builders should focus on proper sealing techniques using silicone and foam tape around support pieces. Installing rubber feet prevents surface damage while providing stability, and applying durability coatings protects the exterior from wear. Strategic internal bracing with wood strips and plywood control panels guarantees structural integrity, while brass standoffs secure electronics without compromising interior space.

Final Sound Quality Check and Calibration

The final sound quality assessment requires a systematic approach using both objective measurements and critical listening tests to guarantee ideal performance. The process begins with anechoic testing in a quiet room using Room EQ Wizard software calibration to measure frequency response and distortion levels. Critical parameters include frequency range verification from 20 Hz to 20 kHz, amplifier stability testing, and Bluetooth connectivity range checks up to 10 meters.

Technicians should evaluate playback quality across multiple music genres while monitoring for common issues like port noise, cone rub, or unwanted hiss. Fine-tuning involves adjusting EQ settings to address any frequency imbalances, optimizing crossover points between drivers, and adding damping material as needed. Special attention should focus on battery performance under various volume levels to maintain consistent sound quality during portable use.

Frequently Asked Questions

How Long Will My DIY Bluetooth Speaker Typically Last Before Needing Repairs?

A DIY Bluetooth speaker’s lifespan typically ranges 3-7 years depending on various factors. Regular maintenance, quality materials, and proper care can extend its life, while environmental conditions and usage patterns impact durability.

Can I Use My DIY Speaker Outdoors in Different Weather Conditions?

While outdoor use is possible, proper weather protection is essential. DIY speakers require waterproof enclosures and temperature-resistant components. Most enthusiasts recommend using these creations in mild conditions or providing adequate shelter during extreme weather.

What’s the Average Cost Difference Between DIY Speakers and Store-Bought Ones?

A budget comparison shows store-bought speakers typically cost $20-50, while DIY versions range from $50-200. Despite higher upfront costs, DIY enthusiasts often value customization over price savings from mass-produced options.

How Can I Sync Multiple DIY Bluetooth Speakers to Play Simultaneously?

DIY enthusiasts can achieve multi-sync through Bluetooth 5.0+ modules and compatible transceivers. Multiple sync options include using dedicated pairing apps, dual-audio modes, or wireless transmitter-receiver setups for synchronized playback across devices.

Will Building My Own Speaker Void Any Warranties on Components Used?

Building custom speakers typically voids manufacturer warranties on most components. Warranty risks include loss of coverage for defects, while legal implications may arise from unauthorized modifications. Builders should carefully review component warranty terms beforehand.